Cryogenic Submerged Electric Pumps

The liquefied natural gas business was in the early and mid-1960s, and the handling and transport of liquefied gas from exporting country to the importing country were required. The cryogenic submerged electric motor pump is a unique centrifugal pump design that specifically developed for handling cryogenic fluids such as liquefied natural gas (LNG), liquefied petroleum gas (LPG), liquid ethylene, propylene, ethane, and various other cold liquids.

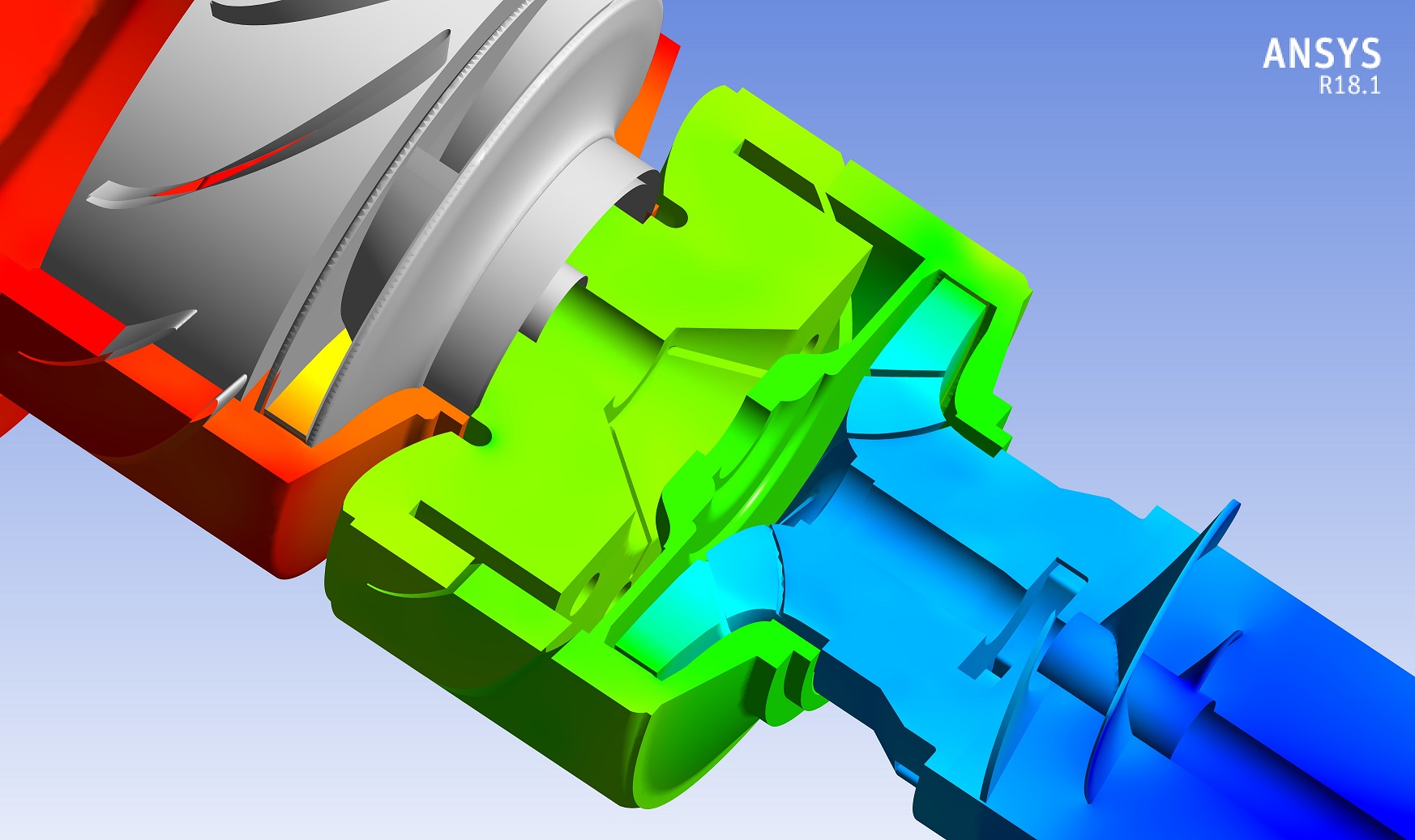

Traditional methods of pumping cryogenic fluids used an external motor with the shaft penetrating through a head plate, extending down into the liquid to hydraulic end. There were serious problems at the penetration of the shaft in trying to provide a dynamic seal that would not leak, mainly due to the differential temperature between the very cold cryogenic liquid and the outside atmosphere. Another problem was alignment of shaft between the motor and pump was very difficult due to the length and differential shrinkage between the materials. Due to inherent problems with traditional design concepts, the idea of completely submerging the motor and pump together in the pumped cryogenic fluid was born.

The pump is seated on a conical seated foot valve adapter at the bottom of the column. The weight of the pump opens the spring loaded foot valve. When the weight of the pump is removed, the foot valve closes. The additional advantages of this type of installation include less external piping and no penetrations below the tank liquid level. The main components of the cryogenic pumps are foot valve, Inducer, Impeller, Diffuser, Balance drum, cryogenic submerged motor, ball bearing and accelerometer.

Contact us: irancfx@gmail.com